Foshan RONDERSON

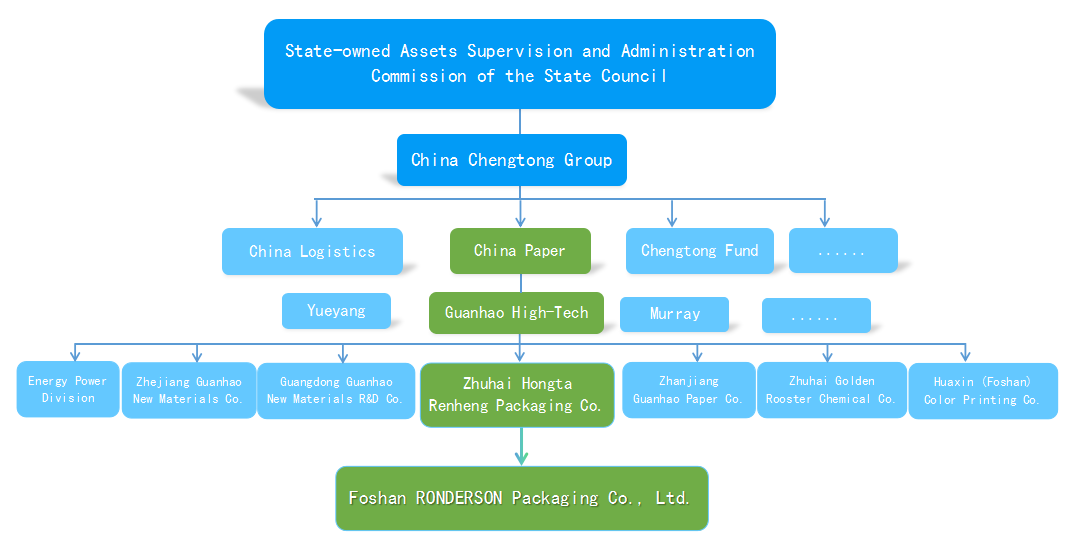

Foshan Ronderson Packaging Technology Co., Ltd. is the authorized core distributor, strategic partner and experimental base of water-based non-plastic coated paper of Guangdong Guanhao High-Tech Company Limited, which is a wholly-owned subsidiary of the central enterprise China Paper Investment Corporation and the only paper manufacturer, and its holding company of Zhuhai Hongta Renheng Packaging Co., Ltd.. The responsibility and mission of Ronderson is to promote Hongta Renheng's leading water-based non-plastic coated paper to the market, actively cooperate with the national and global needs of plastic ban and plastic reduction, provide consumers with more environmentally friendly and healthy, green and low-carbon packaging products, replace plastic and plastic-containing packaging products on the market that seriously affect the environment and human health, and lead mankind to a new era of plastic-free green packaging.